Have you ever wondered why you can’t refreeze raw food after it has been defrosted?

The reasons are mainly two.

The first concerns bacteria: cold has a bacteriostatic function, i.e. it does not kill the bacteria in the food, rather it blocks them, putting them on stand-by.

With each rise in temperature, the bacteria will begin to proliferate again. Hence, with each passage from frozen to thawed (and vice versa), the bacterial colony will be more and more numerous.

The second reason concerns ice crystals. Which, despite the fact that they have a beautiful poetic name, have a negative effect on food.

When it freezes, ice crystals form inside the cells of the food. The slower the freezing process, the larger these crystals will be.

Hence, during defrosting, the crystals break; doing so, they can damage the structure of the product, affecting the organoleptic and nutritional properties.

By refreezing and refreezing the raw product, there will gradually be more consistent breakages of the fibers, and an ever greater loss of nutritional values.

That’s why a blast chiller is indispensable in the kitchen! (yes, I switch to advertising mode now!)

The blast chiller cools the product in the shortest possible time: starting from an estimated average temperature of 70°C, it must reach a temperature of 3°C within 90 minutes and a temperature of -18°C within 240 minutes.

This causes the temperature phase to pass quickly (between 8°C and 68°C) in which the bacteria proliferate faster.

The second pro is that, by freezing quickly, the ice crystals inside the food tissue will be reduced in size: ergo, when the product is thawed, the aforementioned crystals will not break the fibers, thus avoiding changes in the aroma or texture of the product.

So, you need a blast chiller. For both comfort and safety.

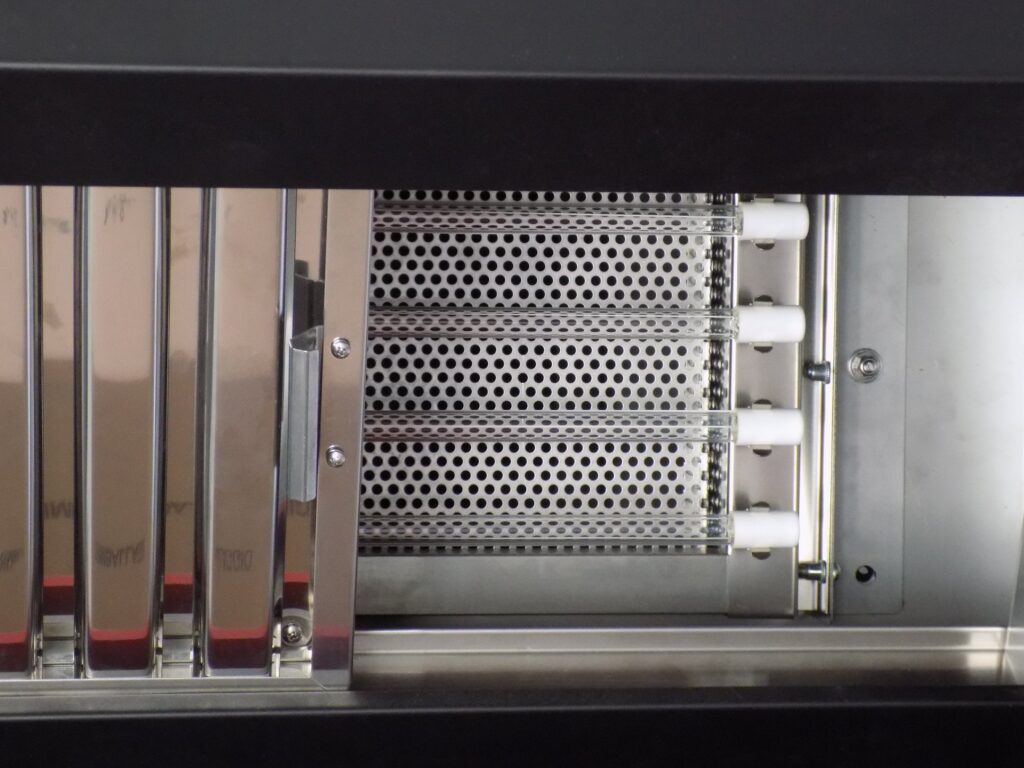

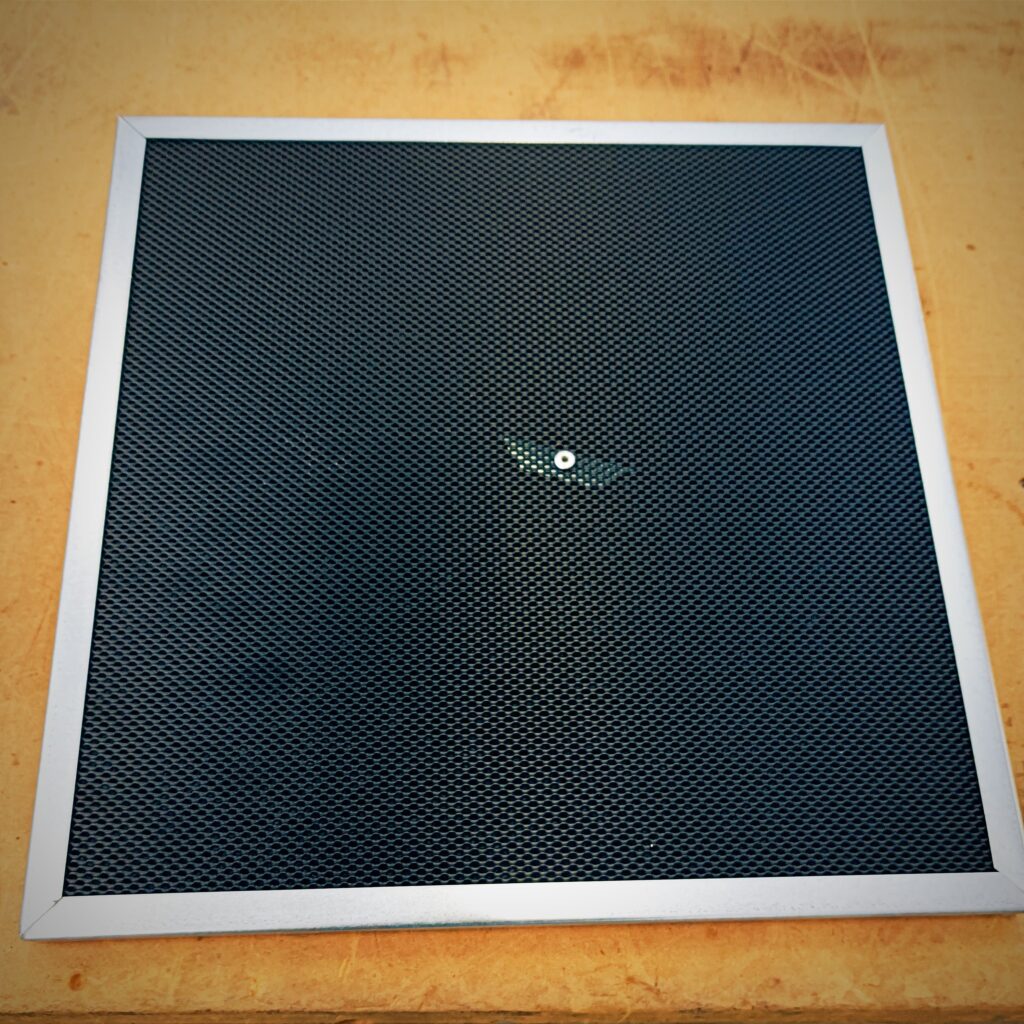

And I happen to sell a few Inox Bim models, including some with digital control!

Italiano

Italiano