An academical British study, Electricity use in the commercial Kitchen, conducted in 2013 and published in “International Journal of Low-Carbon Technologies”, shows off how the Energetic consumption is not strictly related with the volume of meals prepared. Using their own words: “(electrical) consumption is only marginally affected by trade volume”. (here’s the complete article: https://academic.oup.com/ijlct/article/11/1/66/2363520)

As a first impression, it seems like the cost of energy is more likely to represent a fixed cost, not proportionally related to the business volume. And, as we all know, maximizing the gains passes through minimizing the expenses.

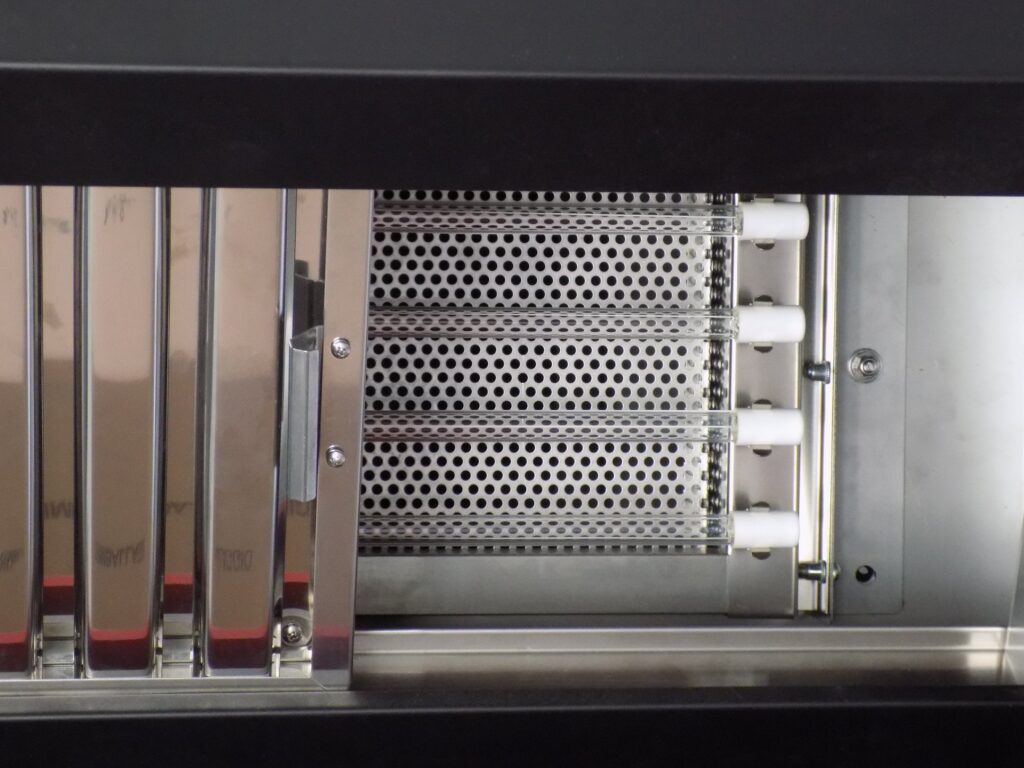

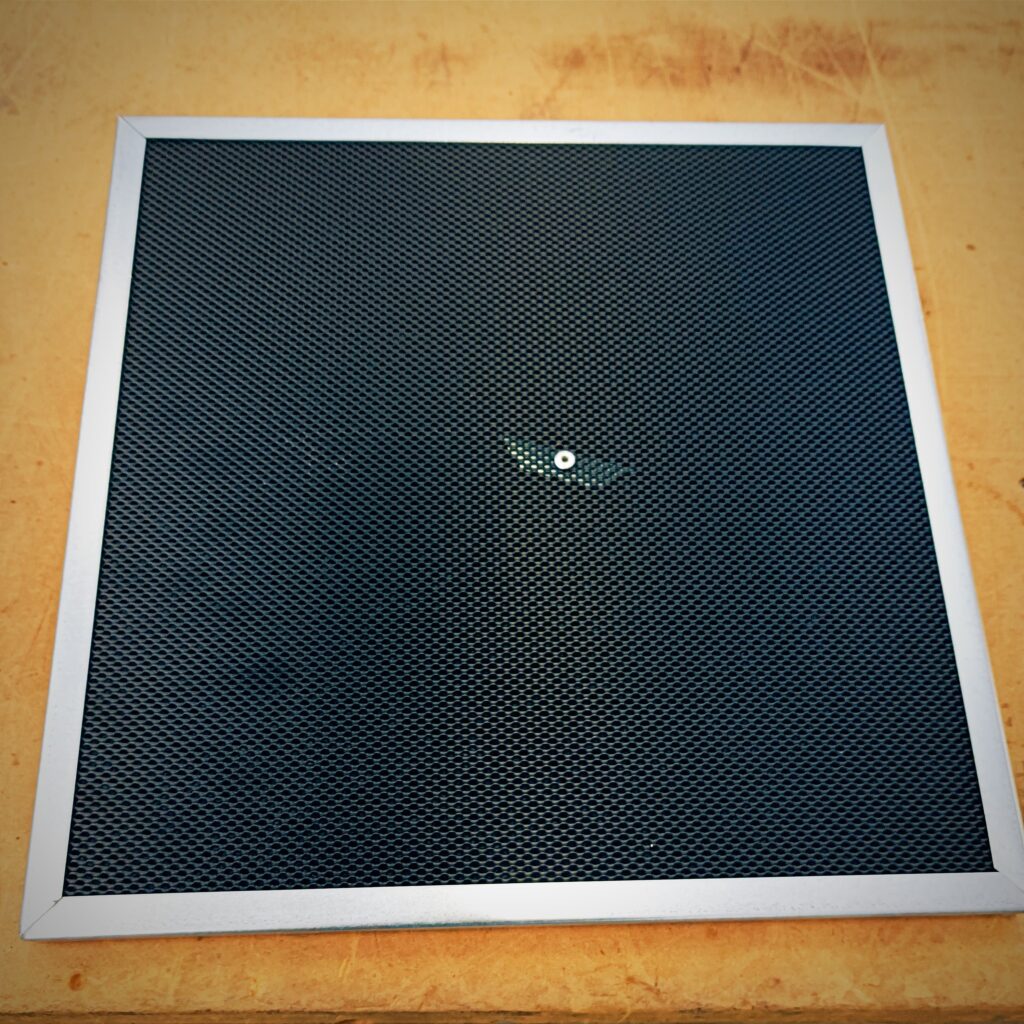

Lots of studies, papers, articles about energy saving in catering business have one thing in common: they outlight the importance of maintenance. Keeping the appliances properly clean will immediately reduce the need of electric consumption for the refrigeration machines, and for gas or electric consumption for the cooking ones. The maintenance and the cleaning must be regular, as a routine, and they would avoid most of the causes of corrosion, deposits and scale that would affect the heating transfer or the performance of extractor canopies, refrigeration units and washing equipments.

In addition to that, leaving the machines in a poor state may cause a damage to it that the manufacturer (or the dealer) may not recognize as a damage coverable by the warranty. Both the EU Commercial and Legal guarantee policies state that the manufacturer (or the trader) is not obliged to cover any fault caused by negligent use. Lack of routine maintenance can be considered as such.

Why maintenance and cleaning are strictly related? Because they both make necessary a training program for employees. As it was stated in a Study made by the British agency Carbon Trust: “because catering is relatively labour intense activity, much of the potential energy saving relate to working practices. The efficient use of equipment in the kitchen will not only save energy and money, but may contribute to a better managed catering operation (…) and, in some instances, better standard food” (https://www.carbontrust.com/media/138492/j7895_ctv066_food_prep_and_catering_03.pdf). Appointing a Kitchen Staff Manager and establishing a schedule are two of the most important steps forward in that field.

Talking about heating machines, another factor is the operator behavior. Leaving the heating machines switched on when not in use, or at maximum power when switching them off is not possible, is one of the most common waist of energy.

Almost 40% of the Daily Energetic Consumption in a Professional Kitchen is due to the Refrigeration Appliances. Mostly due to the fact that fridges and freezer are the only machines that work continuosly. A few simple moves shall be enough to cut also this important source of cost.

Preferring the high-class energetic Machines increases substantially the energy saving, as We can see in the following example

If we examine the median value of the kWh per Year needed by an A-Class 490 liters of Net Volume refrigerated cabinet (350kWh) compared to the corrispettive value of a D-Classmachine (840kWh), We can see a total difference of 490Kwh. Taking into account the average cost of a KwH for non-household in the European Union is 0,112€ per Kw (data of second semester 2017 – source Eurostat), the amount of the money saved per year is, always as a median value, 54,88€ (actually it can go up to 153€ in Denmark, the most expensive European country as far as concerns electricity for professional use). Calculating the 8-10 years of product lifespan, that represents a long-term pay-back investment.

A glass door would also help us minimizing the cost: allowing to check the stock without opening the door, it will minimize the cold air escaping (reducing the number of times the door is open by the operator in charge of this). And, always related to the cold air escaping, frequency of deliveries can also affect the energy performance.

The Kitchen Layout it is very important too. Placing an heating element side-by-side a refrigerator may raise the consumption of this last one up to the 30% (possibly even more than that, in case of a low climatic class). The advise is to group heating and cooling elements in different part of the room or, when that is not possible, to distance them at least 80-100mm, enhancing so the air circulation

Italiano

Italiano